ABOVEGROUND HYDRANT

Features Vertical installation of water or fire installation. Automatic discharge after use. Epoxy coating min 250 μm. Working pressure PN16. Connecting flange according to EN 1092-2. Aluminum couplings

Showing 1–16 of 74 results

Features Vertical installation of water or fire installation. Automatic discharge after use. Epoxy coating min 250 μm. Working pressure PN16. Connecting flange according to EN 1092-2. Aluminum couplings

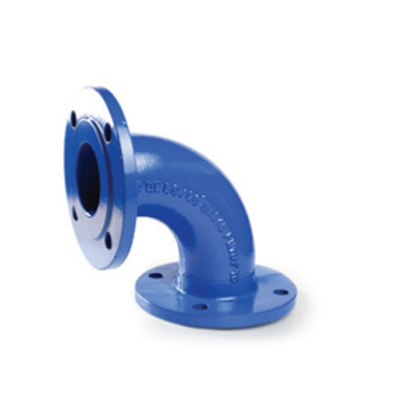

Features Available range of DN sizes DN 50 to DN 200. Inside and outside epoxy coated, min 250 μm. Working pressure PN10 and PN16.

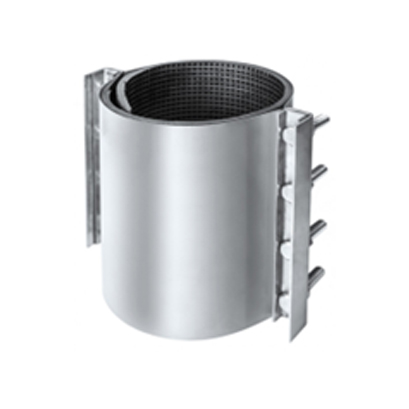

Features: For installation on cast iron / ductile, steel, Asbestos-cement, PE and PVC pipes Produced according to EN 14525: 2004 Surface protection with epoxy paint min 250 μm according to EN 14901:2014 or thermoplastic in black which are confirmed by a report on the health safety issued by accredited laboratory Operating pressure PN10, PN16 Galvanized…

Features Material: Ductile iron GJS, bitumen coated Purpose: Provides access to valves or connectors Versions: Fixed

Features: Dimension Range: DN50 to DN2000. Working Pressure: PN10, PN16, PN25, PN40 Surface protection with epoxy paint min 250μm or thermoplastic confirmed with a health inspection sertificate issued by an accredited laboratory

They can be used for the following types of pipes: Ductile Cast Iron (Dl) gray cast iron (Cl) Steel (St.) Asbestos cement (AC) Steel coated with polyethylene PVC GPR P.E Repair couplings should be used under the following conditions: The scope of the coupling should include the outside diameter of the pipe; The length of…

Features Material: Ductile iron GJS , bitumen coated Capacity: Class D400 according to EN 124 Purpose: Water drainage

Copyright © 2023 Xerxa NPT. All Rights Reserved. Web by: Flutra Webs